Just when there is a plan it all jumps in a hand basket and runs. It is now mid-September there is a chill in the air that is refreshing and makes you think of fires and warm cooking. Instead of working near town in North Dakota and watching the trees turn and preparing for -45 weather, I find myself in Montana. No the trees and mountains Montana but the brown hills, Grose, and windmills part of Montana. As far East as you can go in Montana. Where the wind can blow you away if you’re not careful.

Not sure I use Montana enough but you get the idea I’m out of North Dakota. Yippee! Any time I get to get out of North Dakota even for a little while is a good time. All though the only difference between this place and North Dakota is the line on the map, we will take it! It’s refreshing to be on a new project especially one where they are not worries about setting new records. A lot of rigs today and companies are all about how fast we can get it done. This project realizes that to make money you have to spend money and they are spending on quality equipment and quality personnel and they want it done right even if it takes that much longer. Time is not the problem. And that is just fantastic! (what a pleasure to work for that mindset)

Seeing as I have a moment I want to explain a bit about how the oil gets out of the ground. There are two types of oil extraction: the conventional and the unconventional. These days the unconventional is actually the more common at least in this part of the world. It’s the type that people have heard about in the news. To get the oil out of ground a hole is drilled horizontally and then the formation is pumped full of water and sand. The water to separate the grains in the rock and the sand to hold them open so the oil can flow out. In short fracking. This is the extraction method that gets a lot of negative press. Most of it is not accurate but that’s for another time. The second type the traditional way as it were is a little more involved. With fracking you can afford to be a little less precise with where you put the wells because as we say it all fracks. You can run wells very close and very vertical as if the army engineers had laid out a grid. With the conventional you have to go where the oil is. To get the oil you have to strategically place the wells because the oil is trapped between water and a hard rock usually on an anticline or syncline. This is the way they use to get oil out of the ground everywhere. They still do this type of drilling in places like Saudi Arabia and parts of Texas and in the gulf. Depending on the pressures in the reservoir, sometimes the oil is in such a hurry to get out that it’s not necessary to pump it and it’s just more of a collection process. When the reservoir is over pressured like this to keep the oil flowing an injection well is drilled to a depth below the oil and water in injected in the system. These are the things the petroleum engineers think about and work on. Luckily for me I don’t have to worry about most of that. But when we do it makes for far more interesting geology.

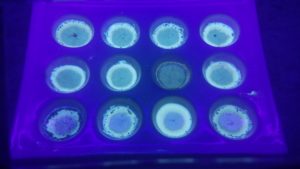

How did I get the lucky straw to get this assignment you ask? Well! I got lucky straw because the new rig I was supposed to be starting up got delayed. Like a lot delayed but that’s okay because now I am here doing something I have never done before. They also send me here because I have to act as a mentor and teacher for a new hand. So far we have covered how to do a lot of the paperwork and the proper way to cut the sample to see if there is oil in them. (Hint there is oil!) Tomorrow we will cover more paperwork and what to get at Walmart. When we are this far from a big town you have to plan strategically what to get. Paper towels and toilet paper are always on the list.